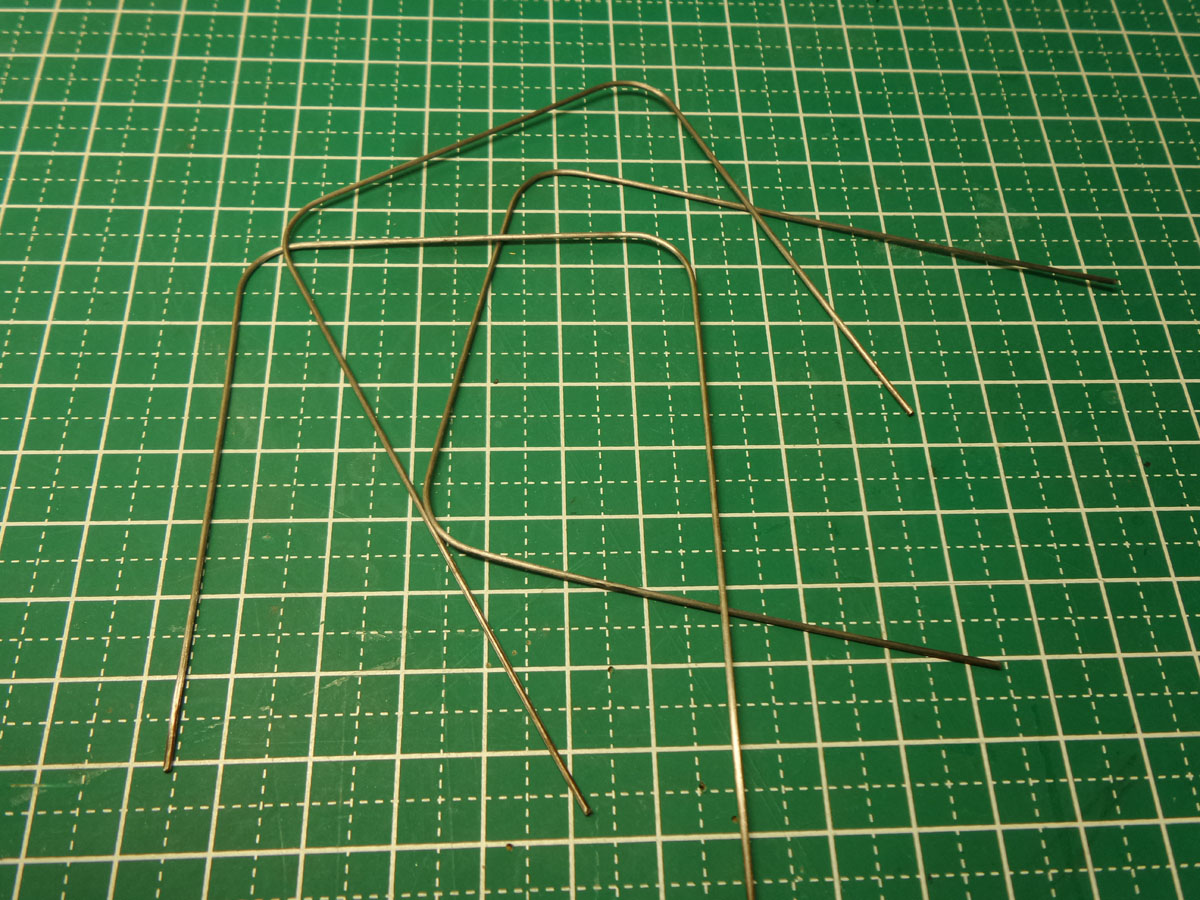

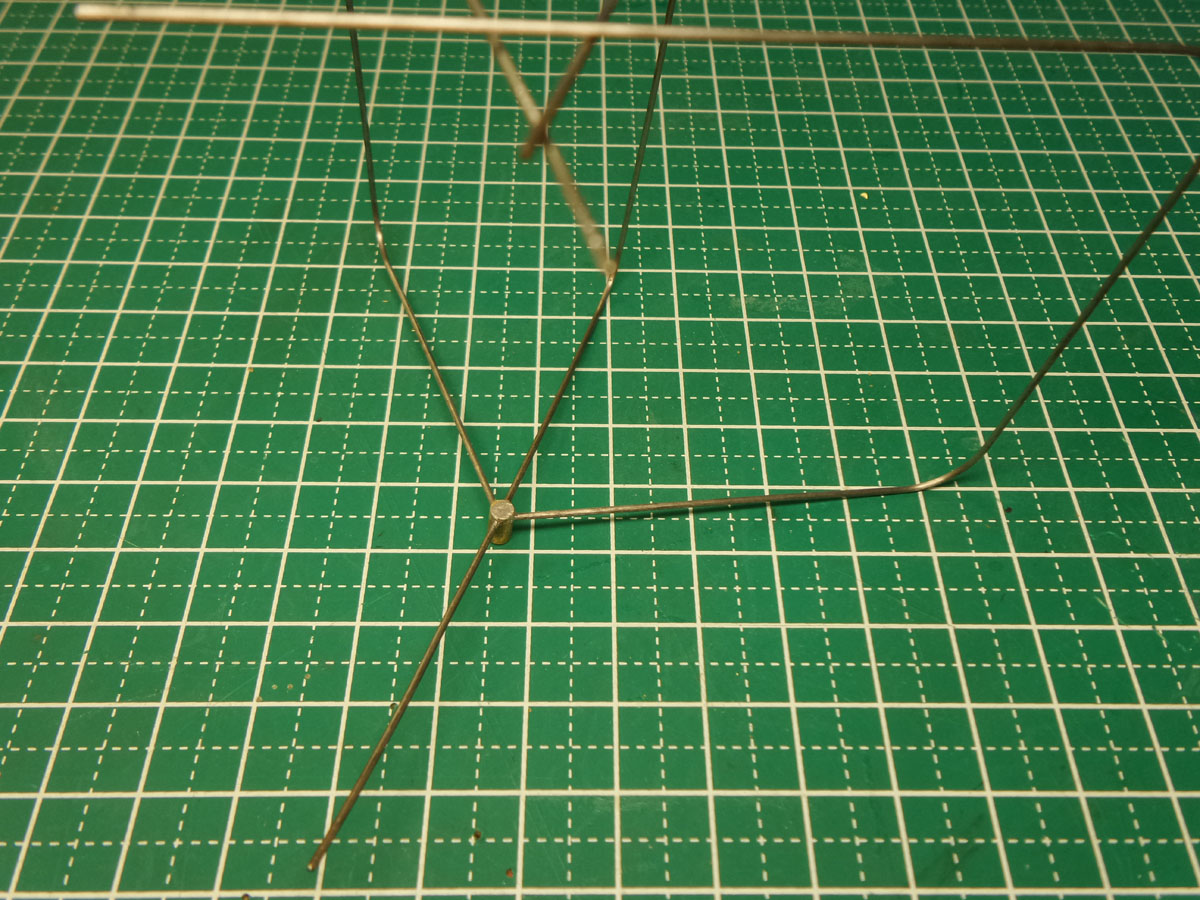

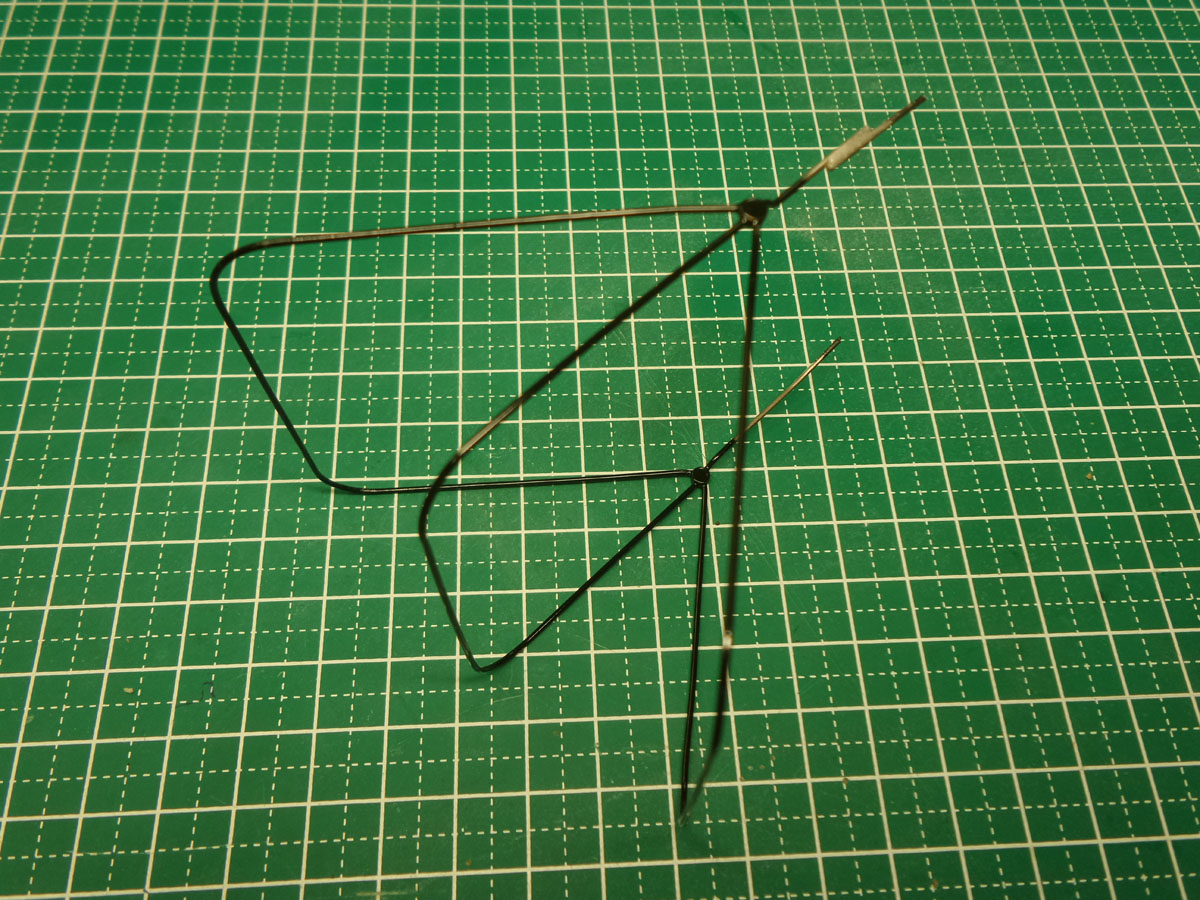

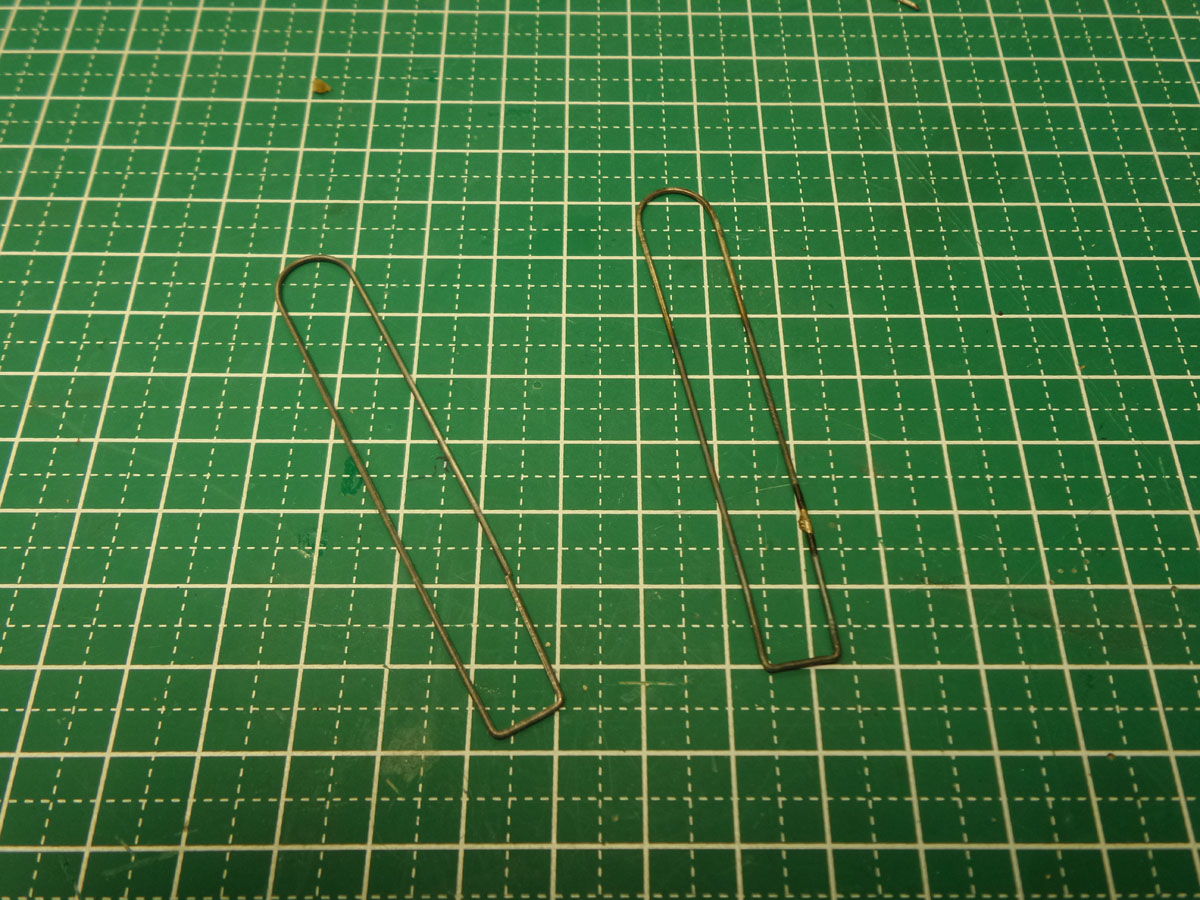

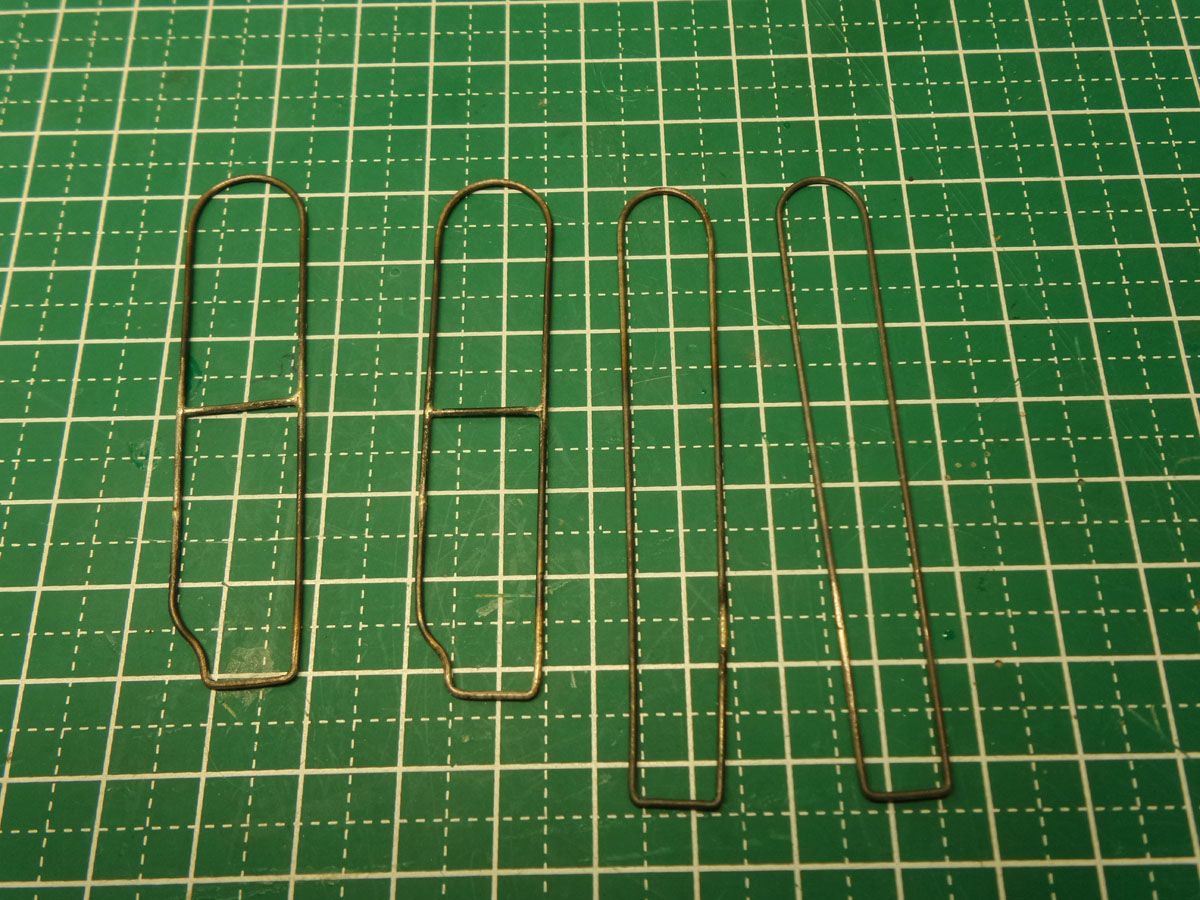

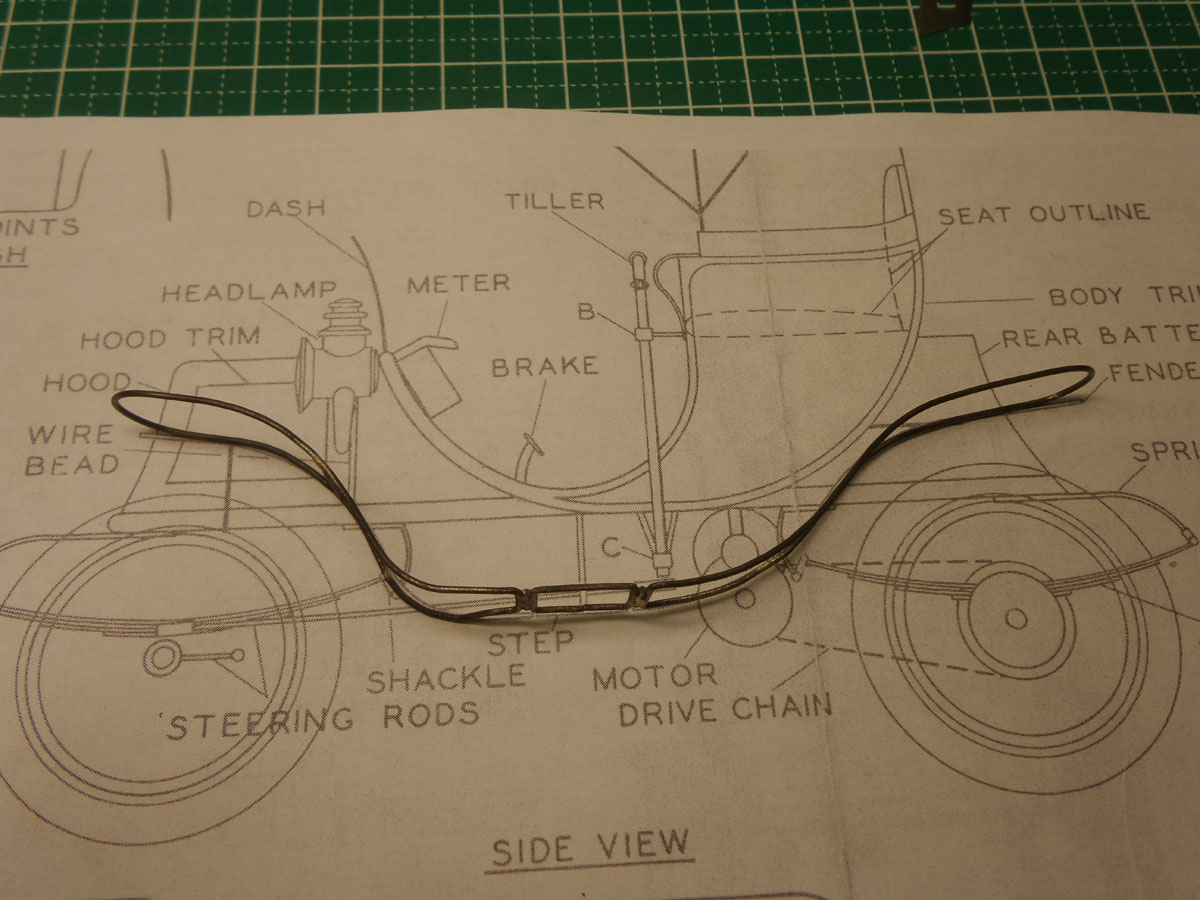

Now the most difficult. Fenders. At first according to the drawing I bent a wire. I used a wire from a set. For bends I used various round objects. Behind that I have soldered the ends with silver solder for rigidity. In general I soldered everything silver solder with gumboil.

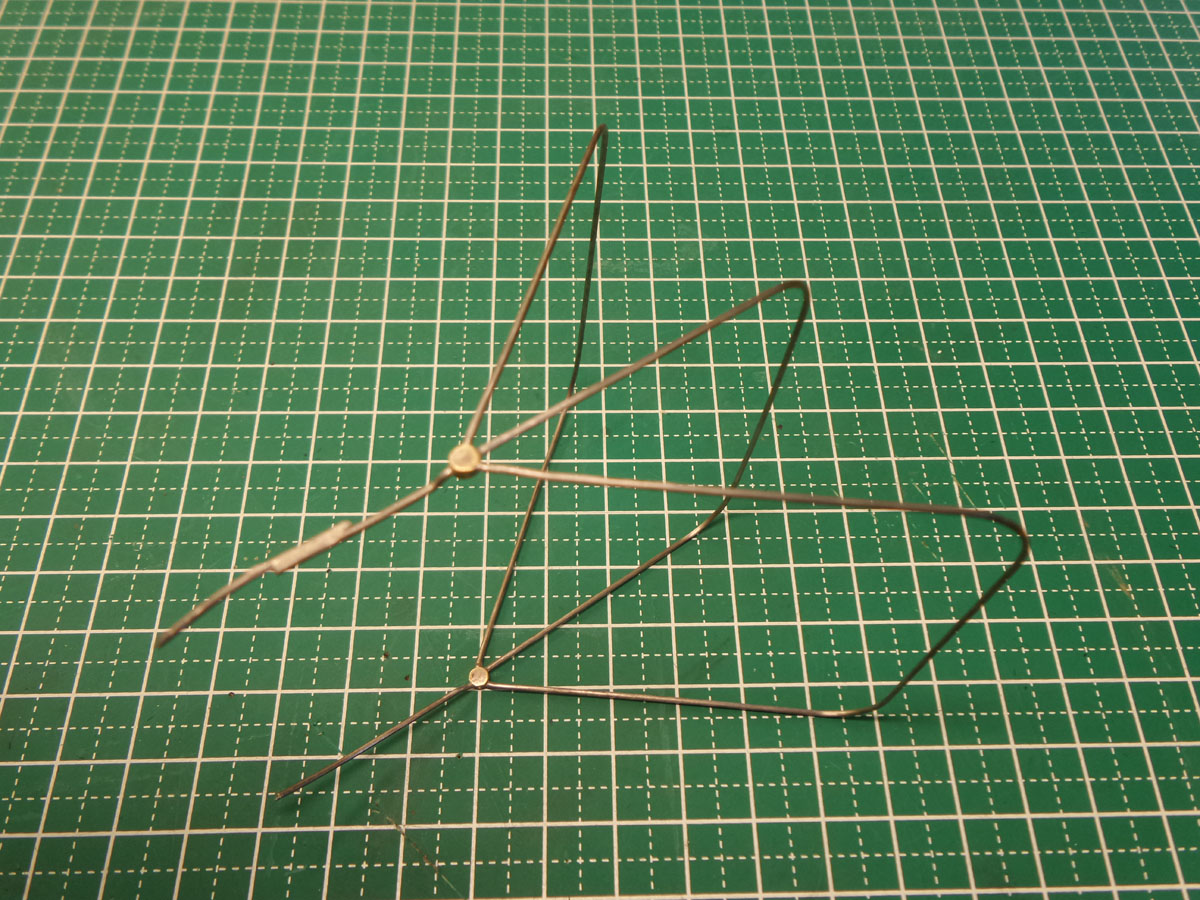

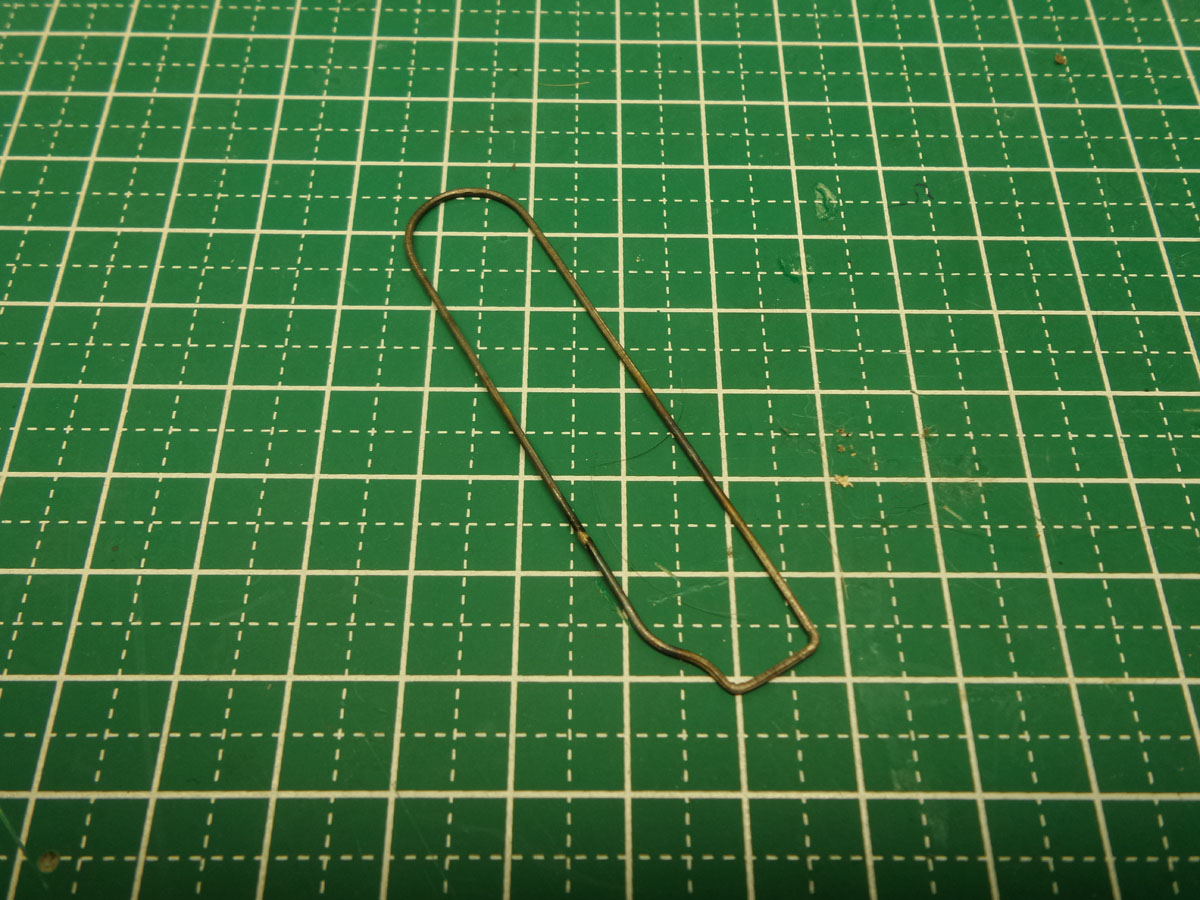

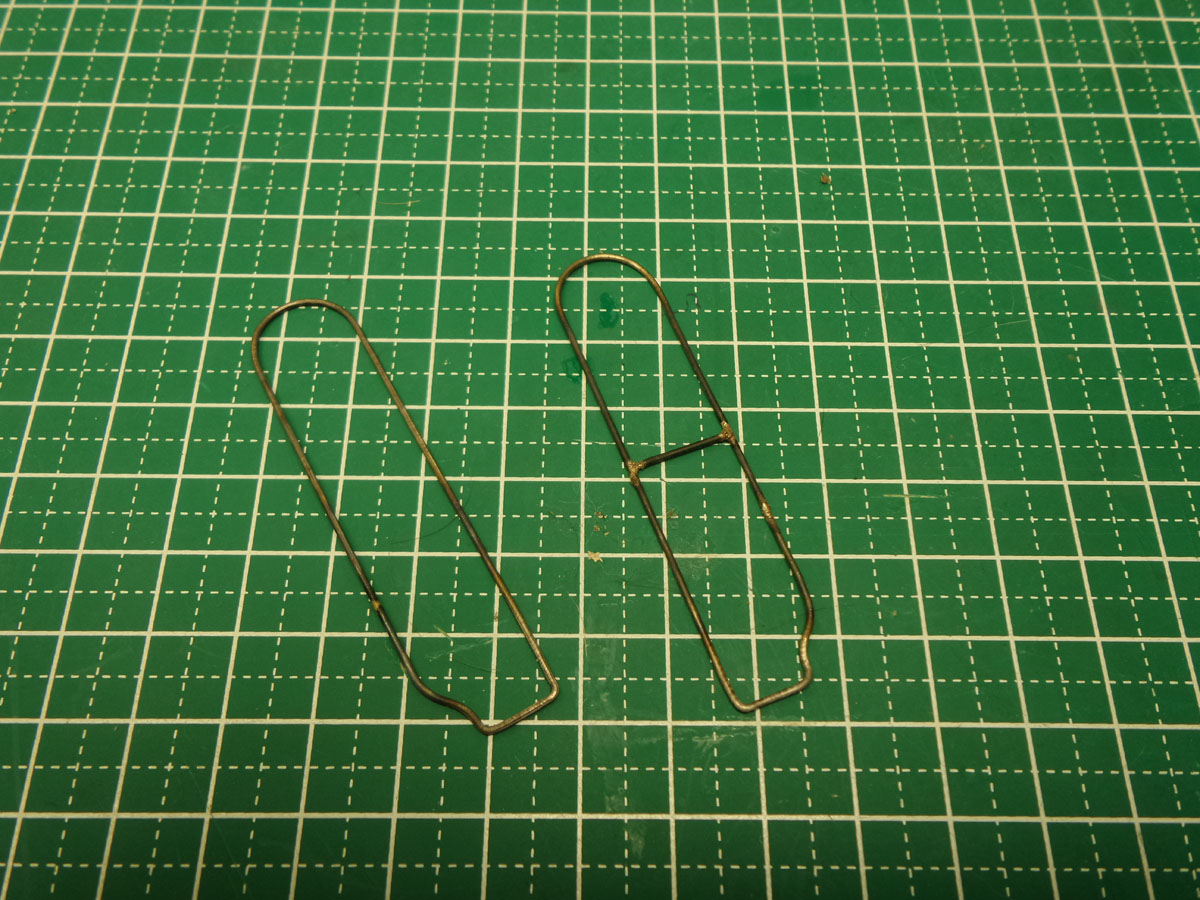

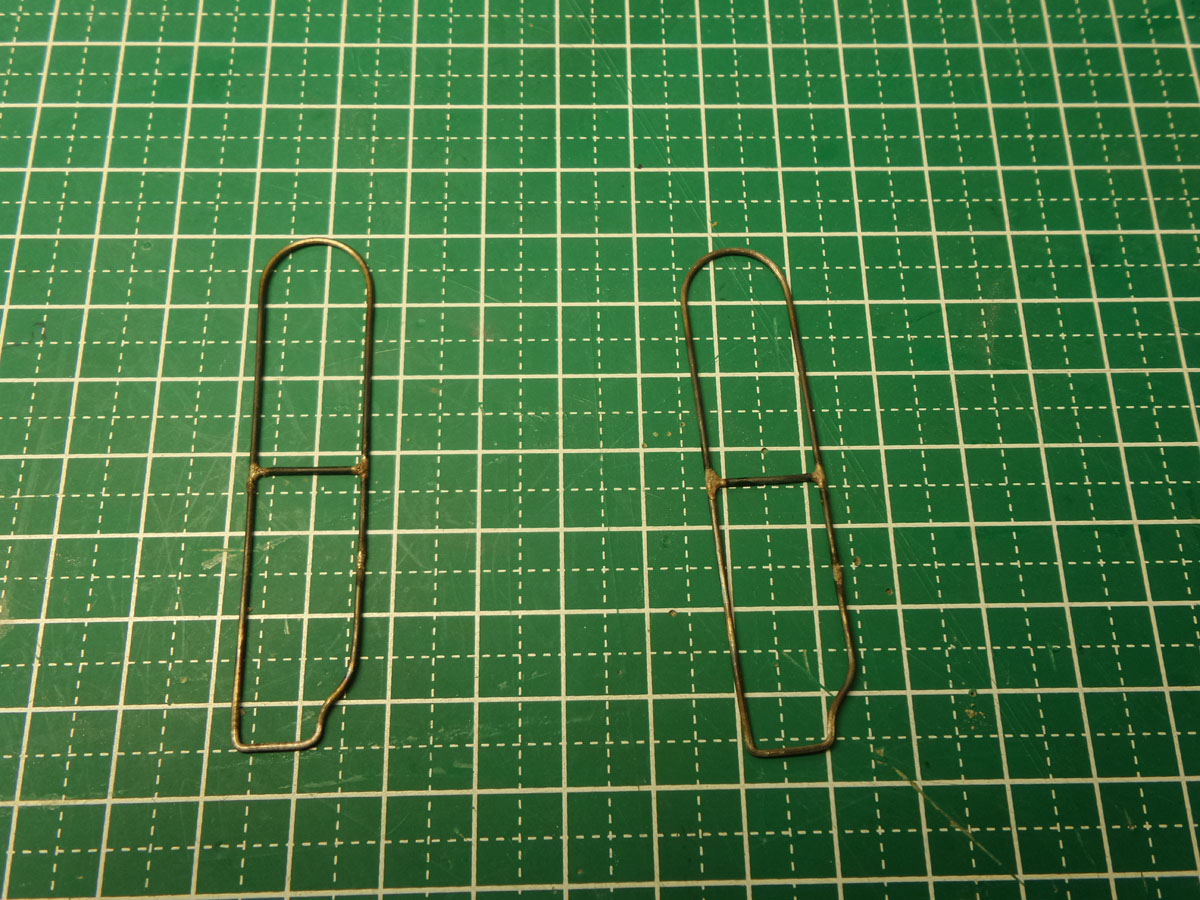

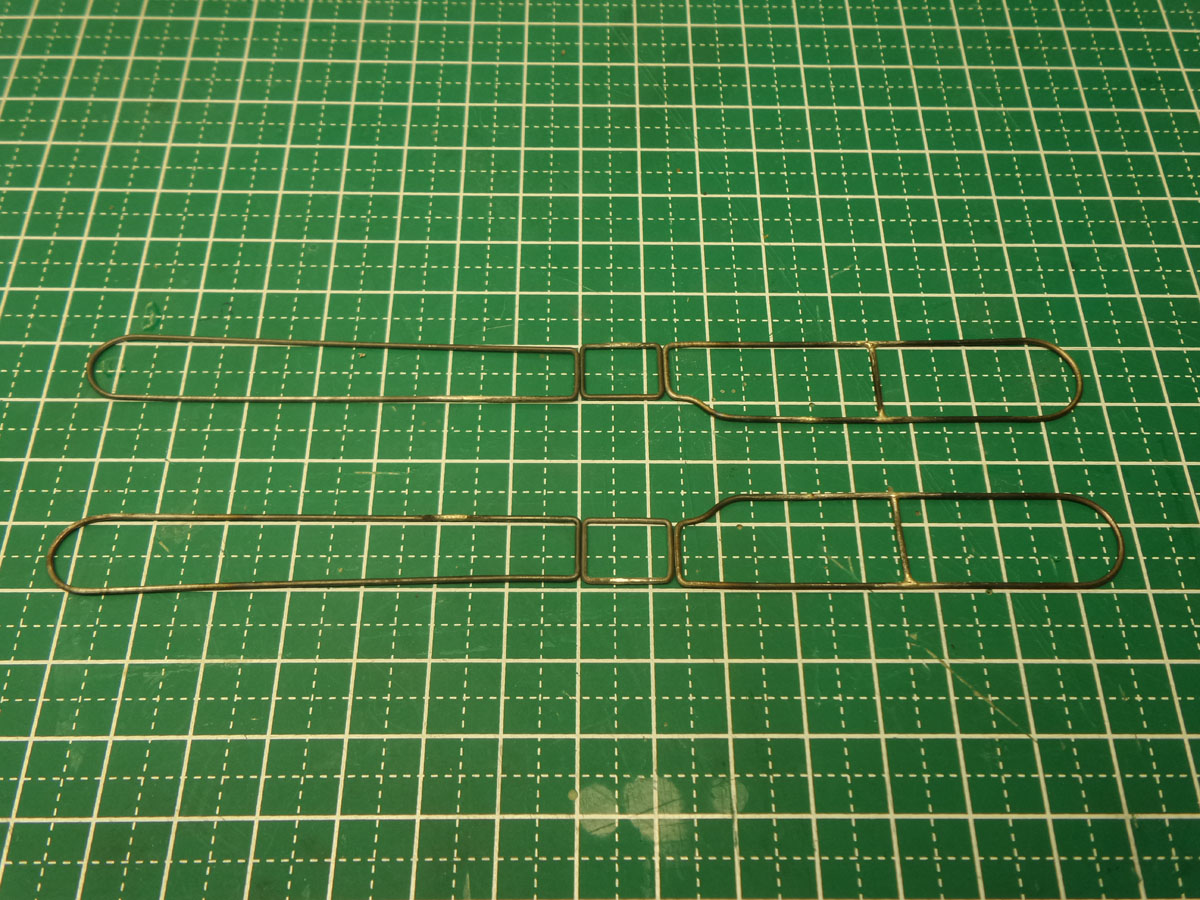

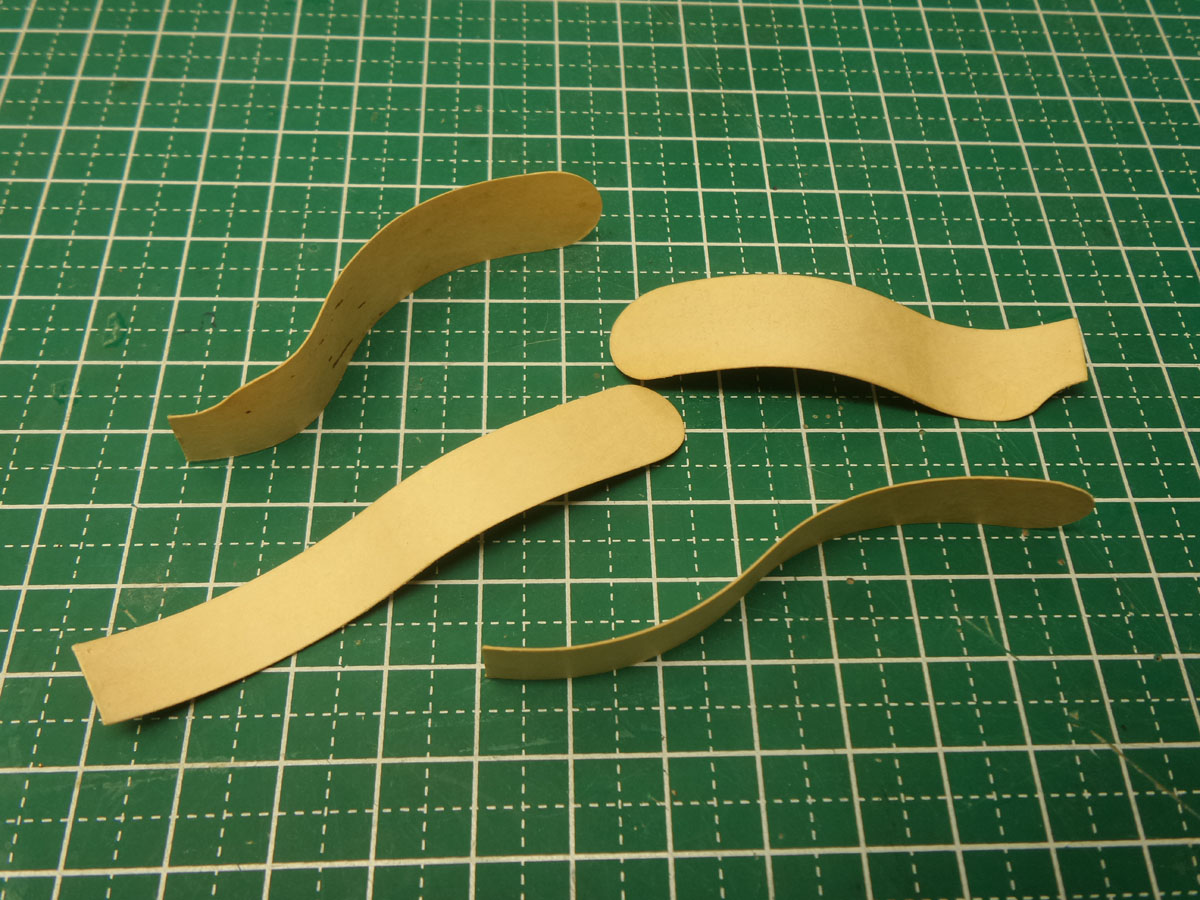

After has made forward fenders on the same technology I have made back and a footboard.

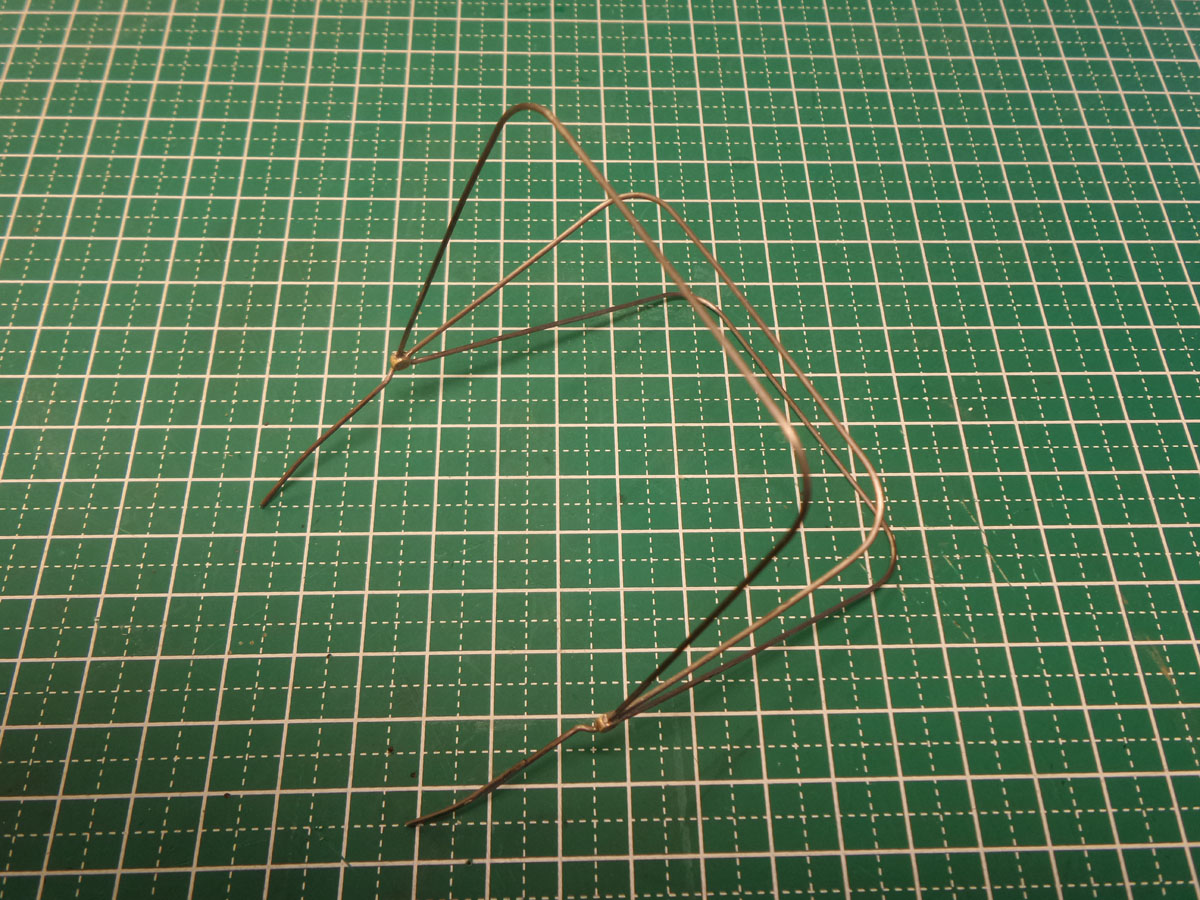

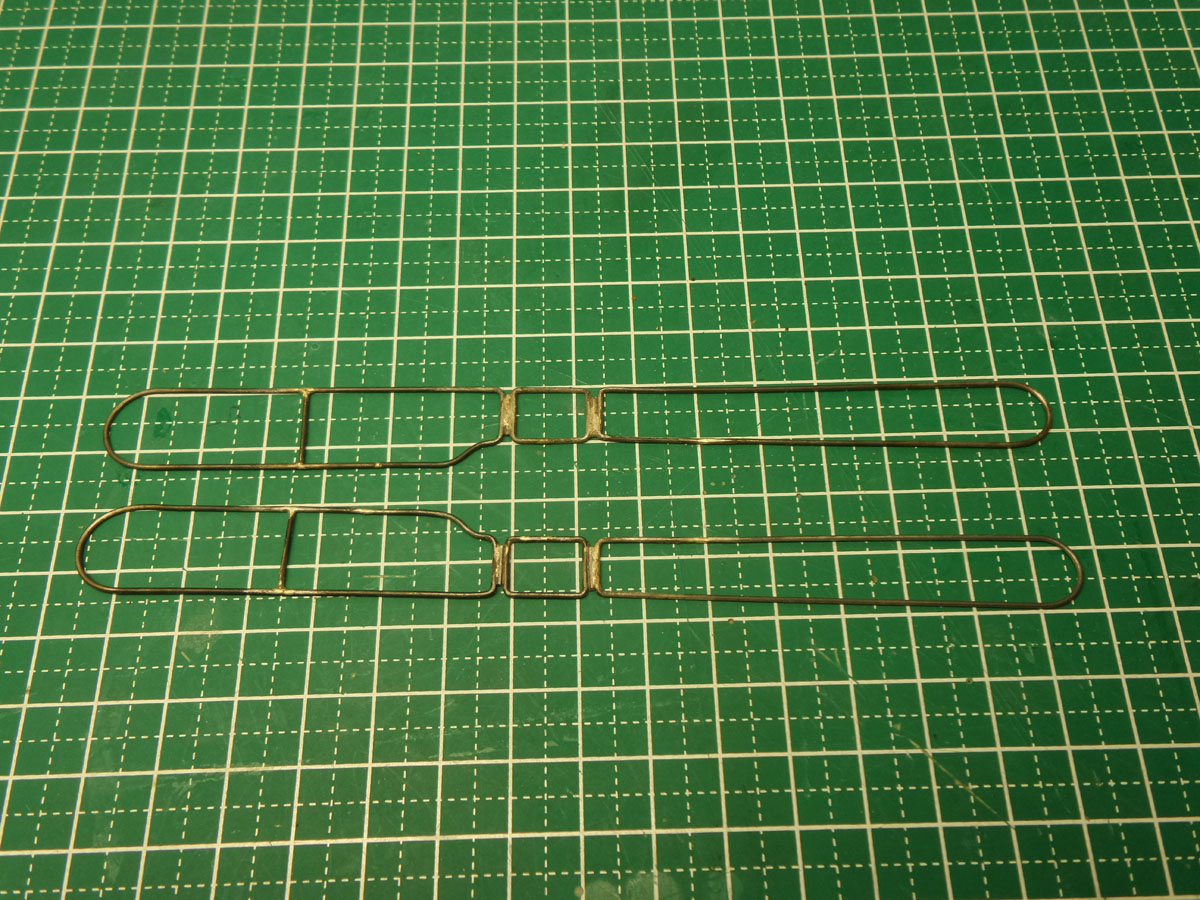

Further I have departed from the instruction and have decided to solder all this together. Only for bigger rigidity and convenience of fastening.

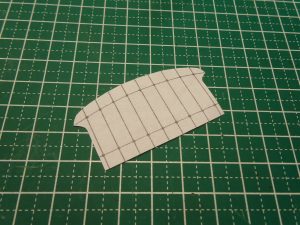

By means of the hair dryer and water I have given to cardboard fenders from a set the necessary form. But before it on a template in the instruction I have bent a metal basis of fenders.

Part 13

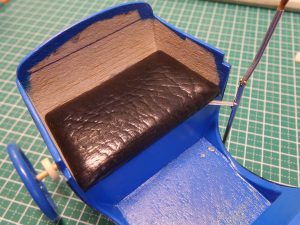

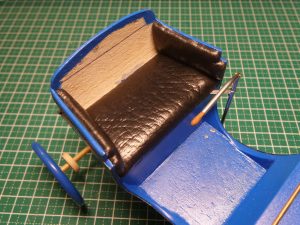

In this part I will tell as did a seat. For a start I cut out a seat basis from balsa. I cut out a sealant of a seat from a packing material and a box of the switcher . I have pasted all this on a basis.

As an upholstery I use thin to skin substitute.

At first I moisten one edge with glue and I paste in skin to substitute. Behind that I paste by the same method lateral faces. On corners I try “to pull” as if skin on a corner. The last I paste the last side. After glue excess skin dries I cut off an edge. Here and the seat turns out.

I do by the same method seat sidewalls.

For a seatback at first I cut out a template and I adjust it in the place. Behind that I cut out a plate from balsa and I fit to skin substitute as a seat.

There now somehow so. The seat is ready, it was necessary to make imitation of an insertion. For this purpose I used small brass nails which I blackened. Behind that on a marking I just stuck them in a seat through. I fixed nails from a reverse side, having greased them at first with glue. Later I cut off superfluous. Most I have made also on a sitting back.

Here the seat is also ready. But I haven’t pasted him into place yet – still early.

Part 12

Is made not much. I have soldered pedals of management from wire and the sheet of brass. I have made the handle of switching of mahogany.

I have made a roof framework of set bars. Without this element it is impossible to begin production of seats – it is necessary to know where and as the framework will be fixed. As a connecting element I used a brass tube. I have fixed everything tin and I have painted black color.