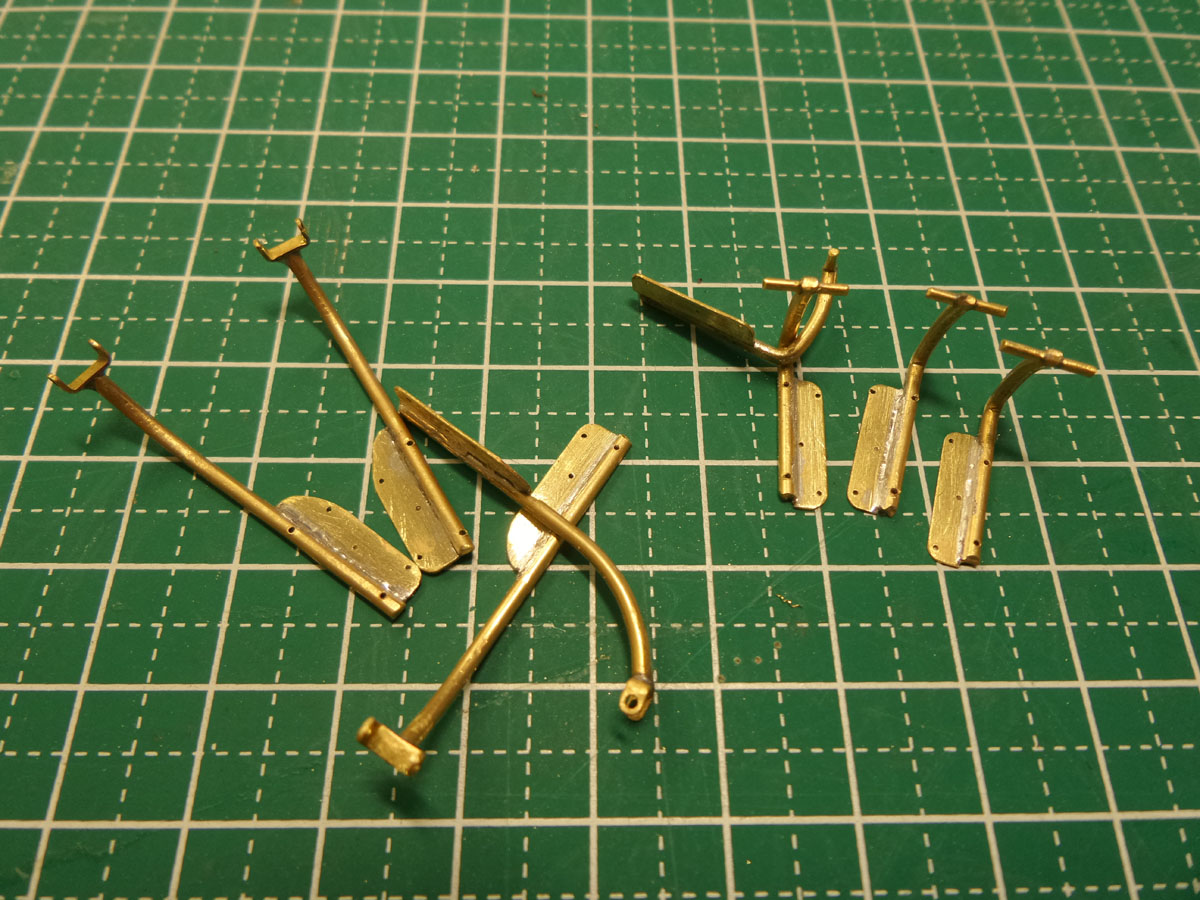

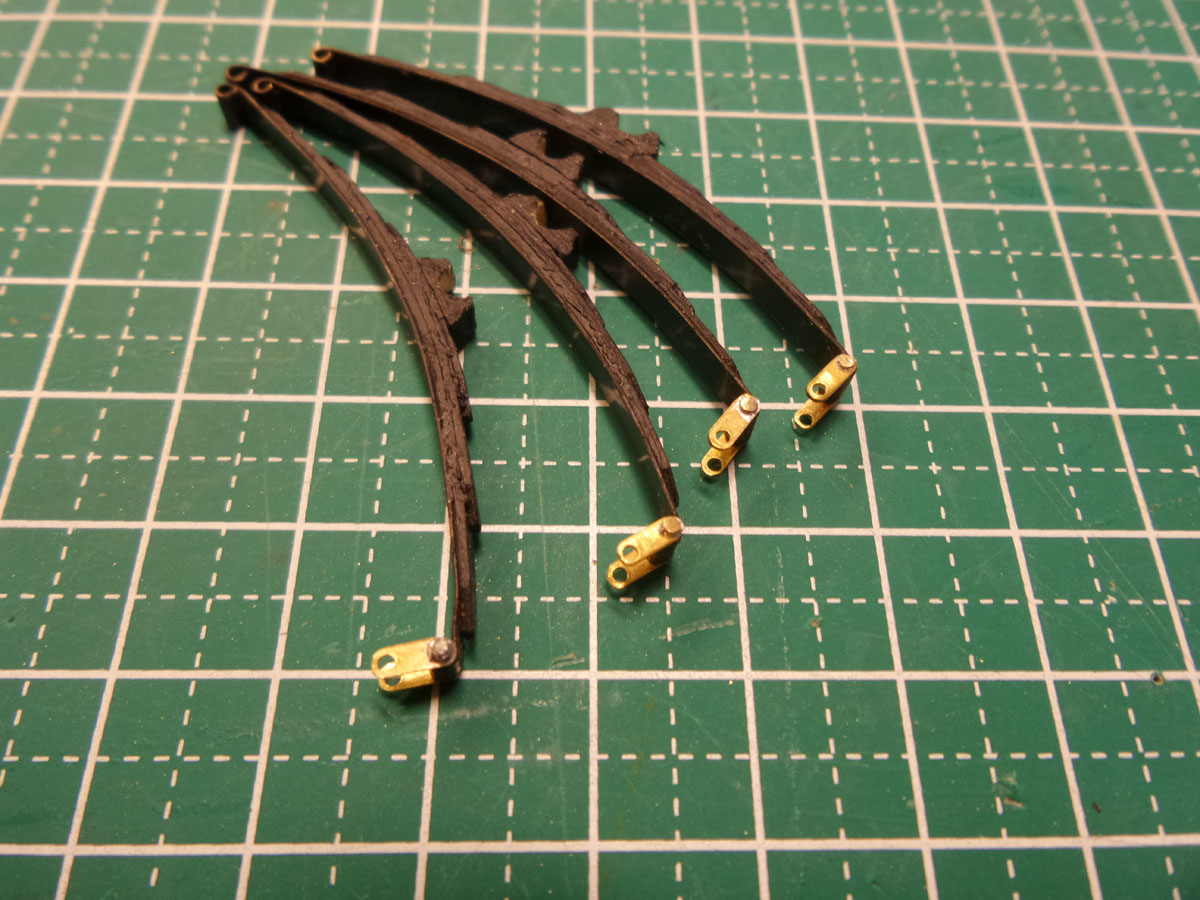

This part short. Is it seems made much, and there is nothing to show that. I have carried out a plumbing, I have soldered platforms on holders of springs and I have drilled openings for a fixture. Also I have recorded earrings on the ends of springs, with the soldering too.

Well and for ink it. It seems everything for installation of a running gear is ready.

Be continued.

Part 5

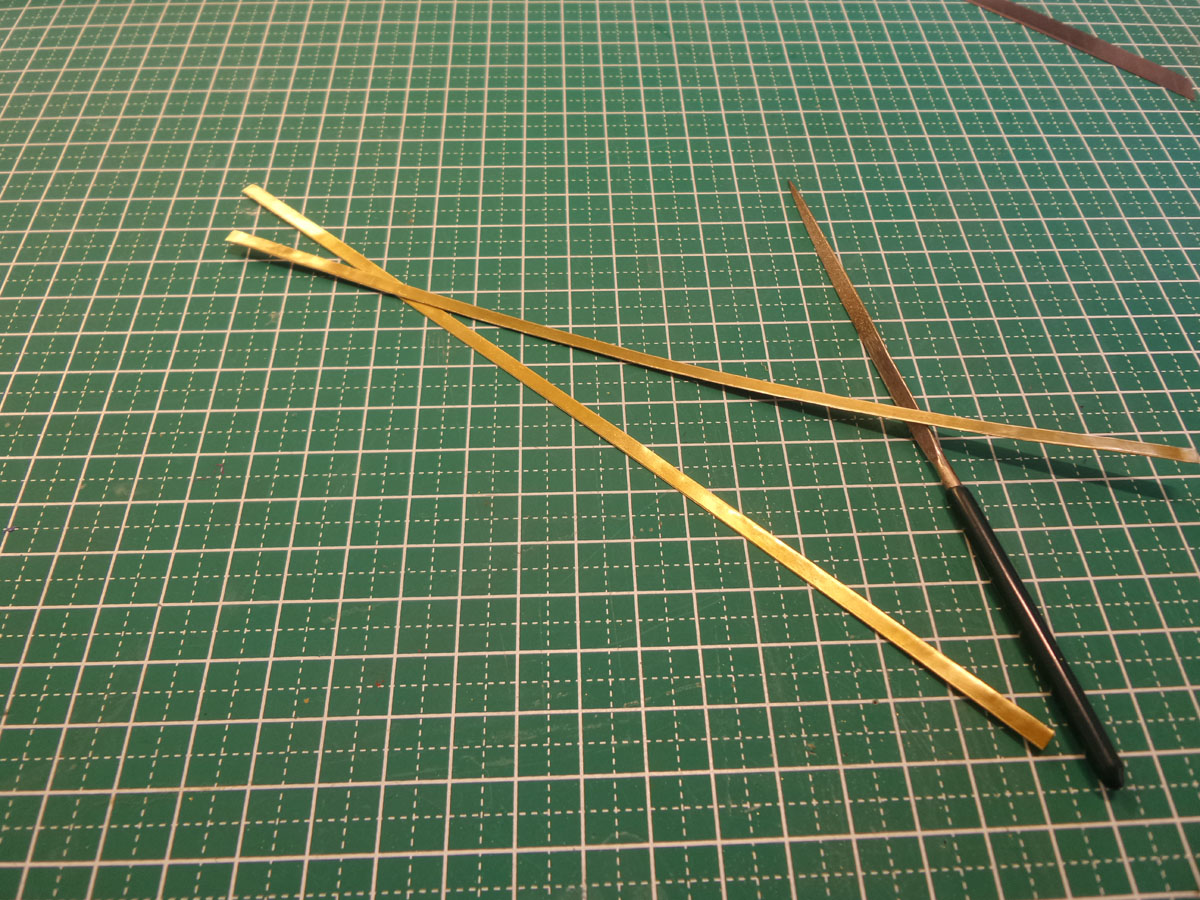

So far the case, and it somewhere for about a week dries, we will be engaged in small things. For example springs. As I have told earlier, I will do springs anew. From a brass leaf thickness 0,4mm cut out strips for the first leaf of springs.

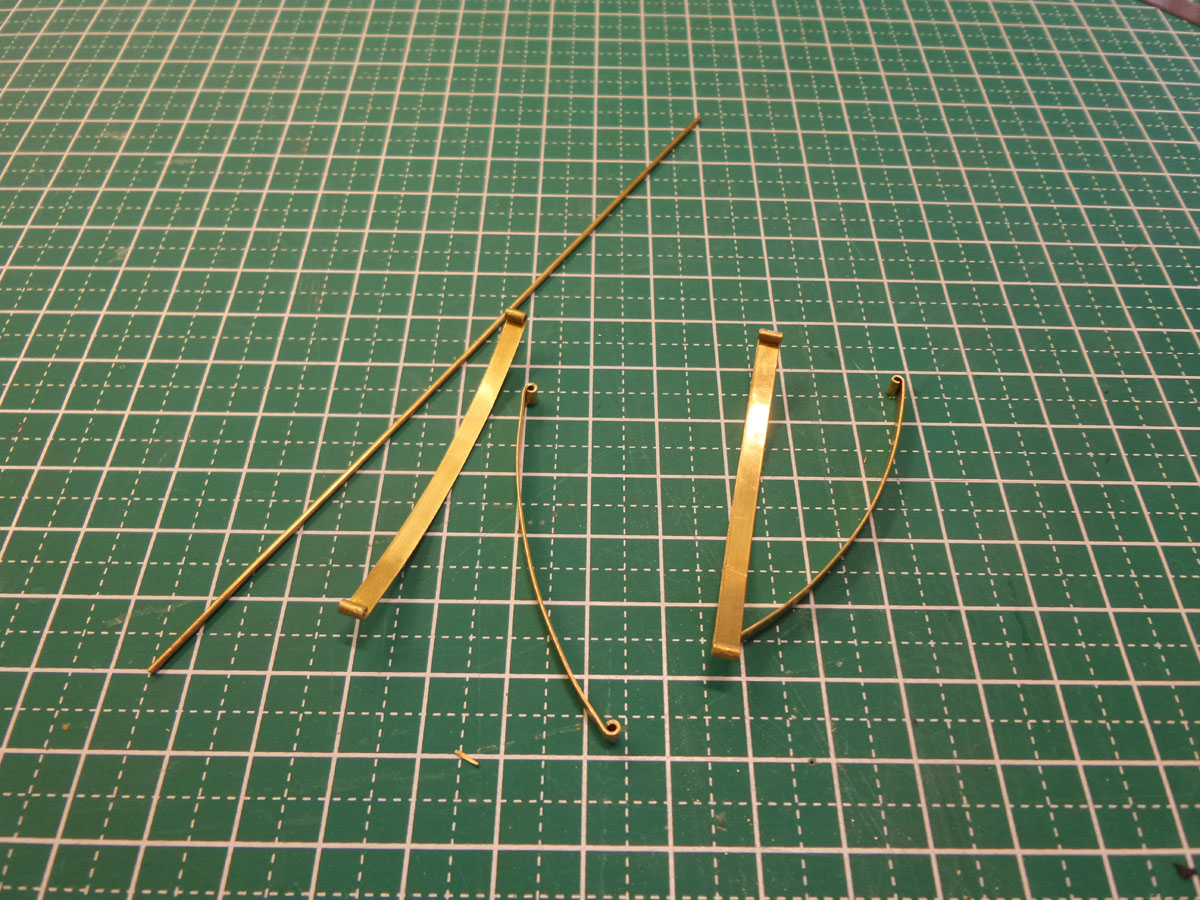

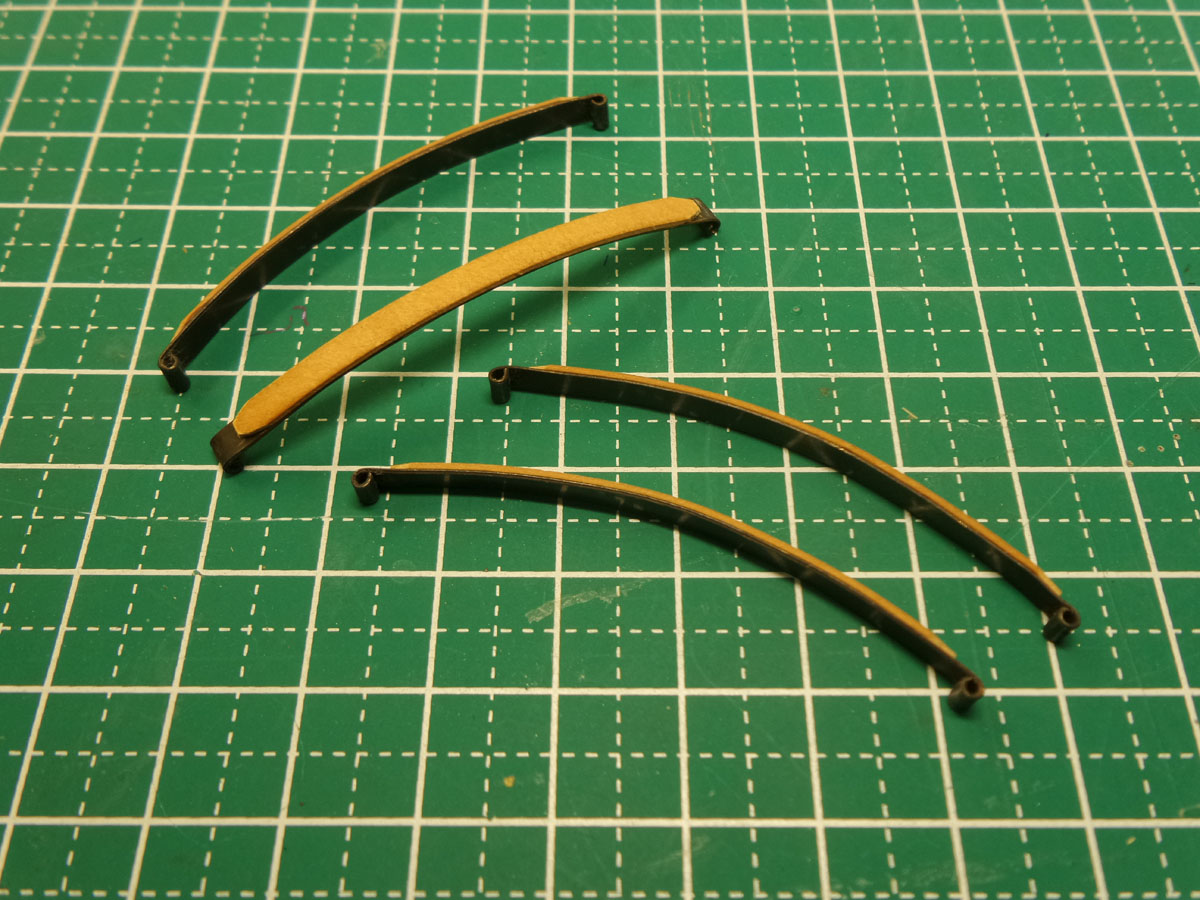

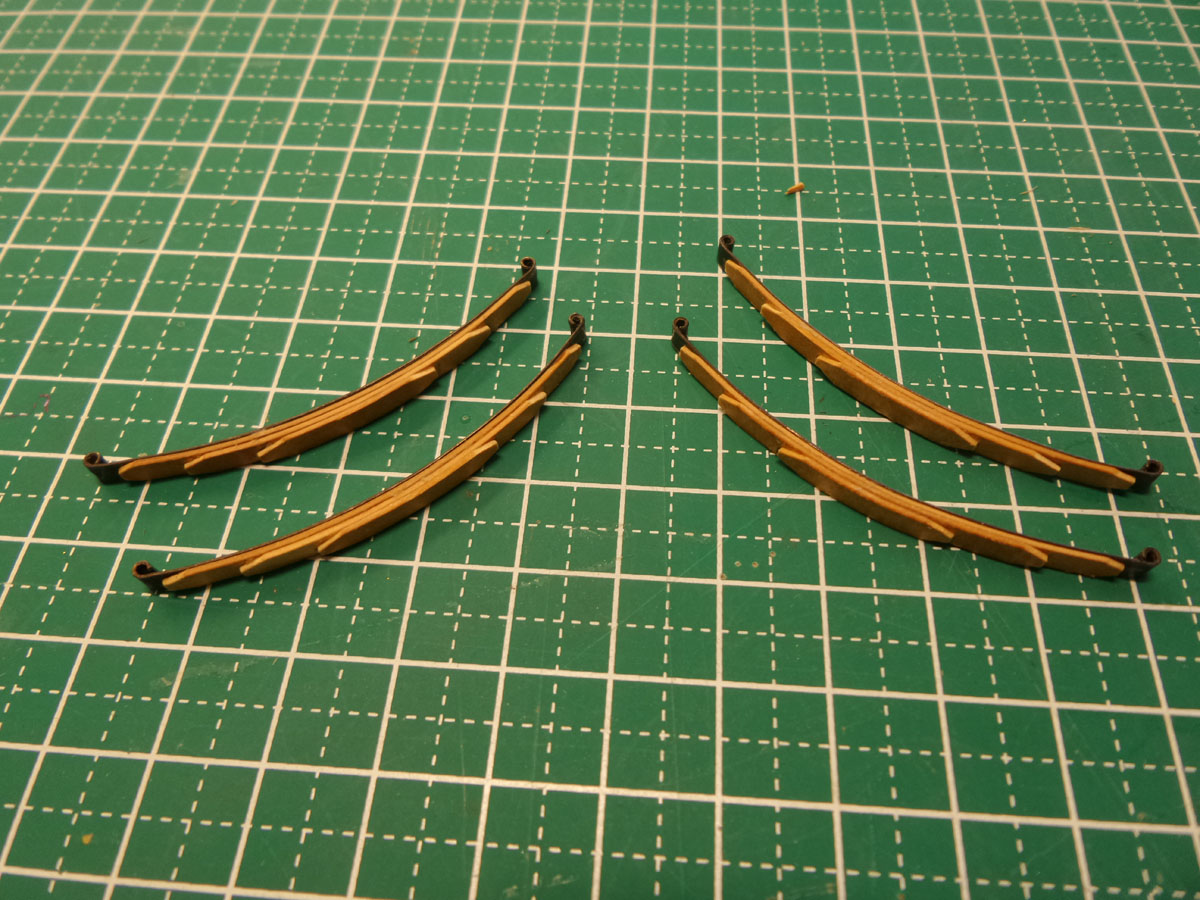

Behind that I have made the first sheets, having bent them according to the plan.

As the subsequent sheets I used the cardboard strips saved from the previous sets. The first cardboard leaf glued on superglue, the subsequent on PVA. I have missed the mark end faces of sheets with superglue for flaking avoidance. Sets of springs turn out rather strong, is checked.

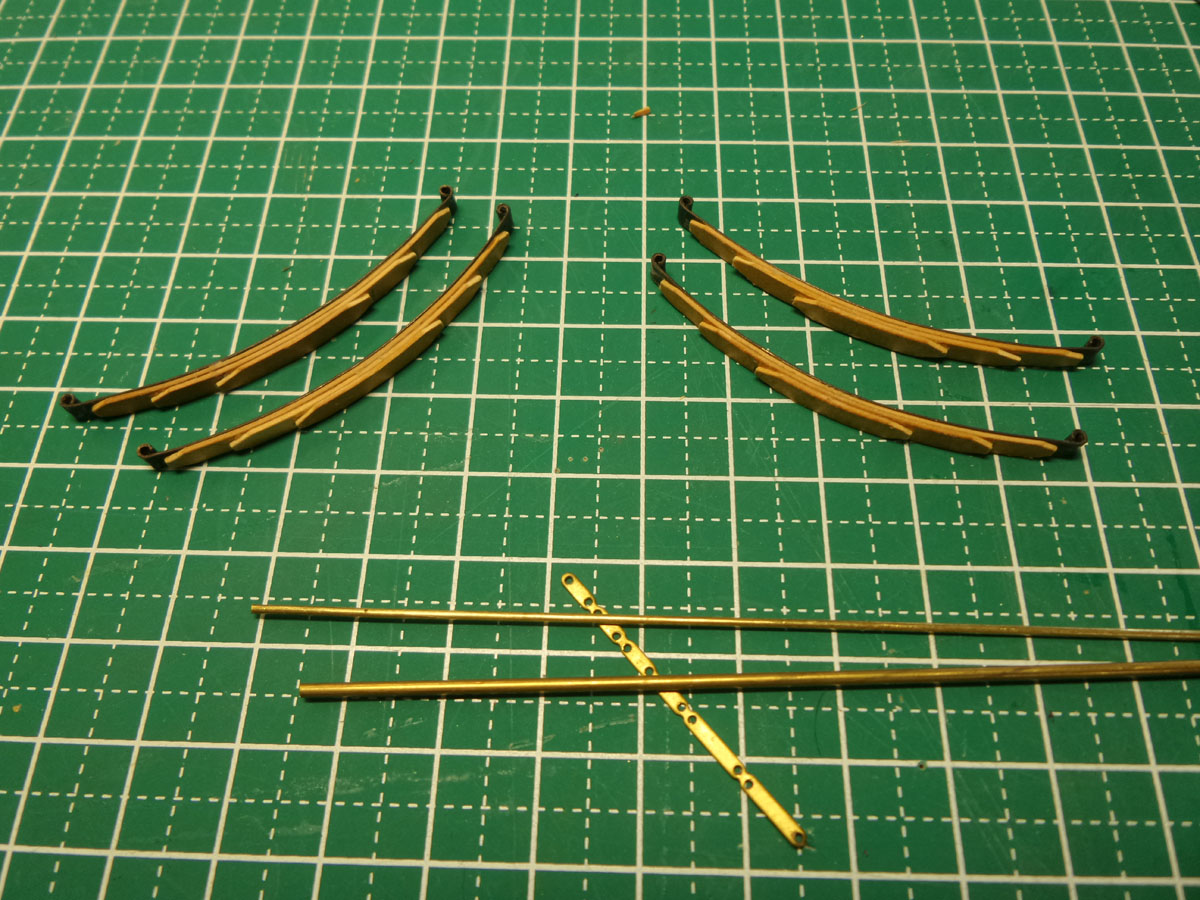

Further, using something from a set and I have made own stocks holders of springs.

As sets of forward and back holders of springs identical, it has simplified production. I soldered tin and orthophosphoric acid. I will cut off lengths of preparations after fitting on the case. It has begun so far, to be continued.

Part 4

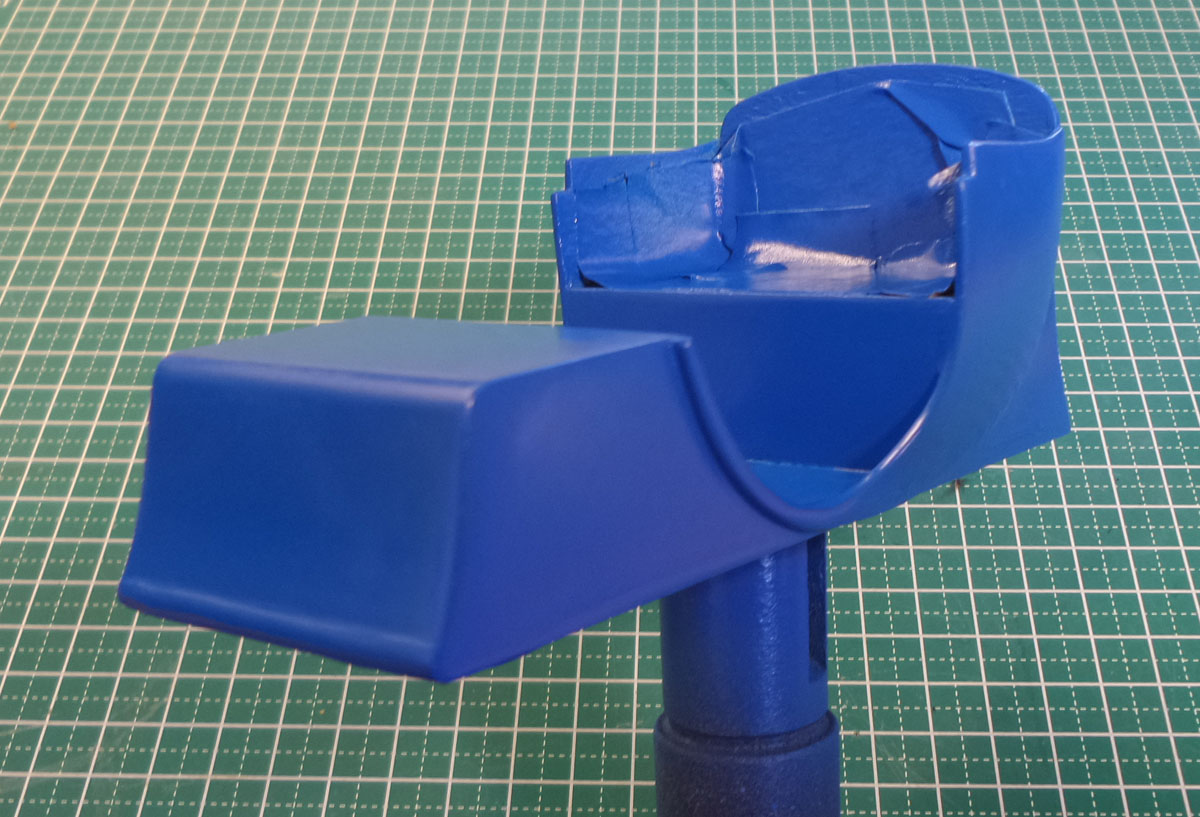

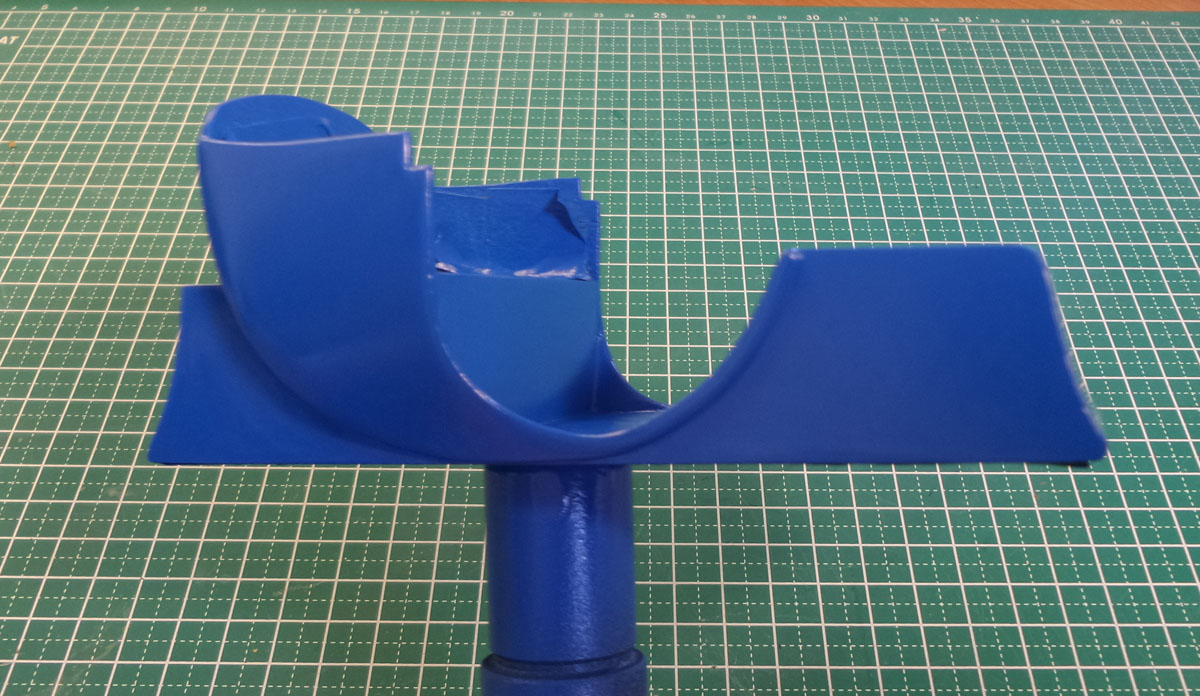

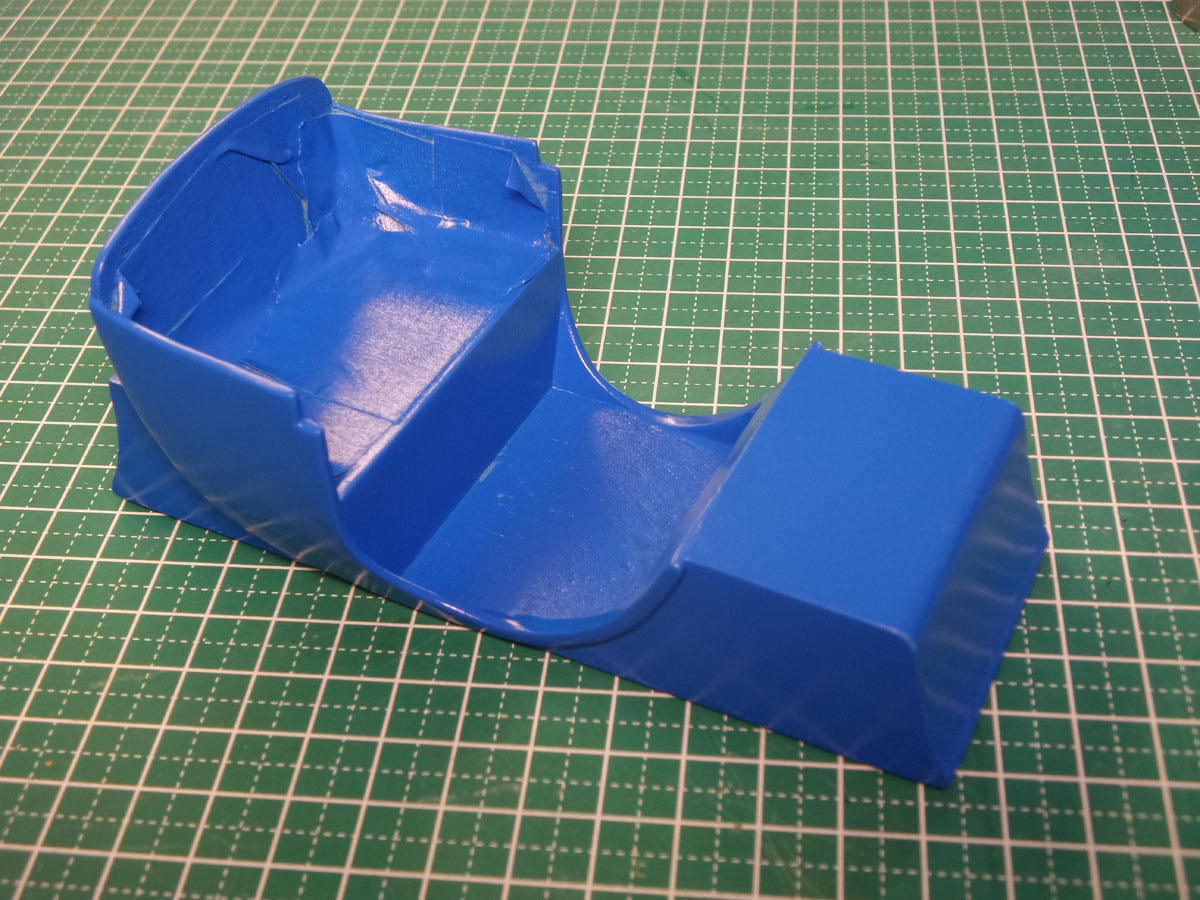

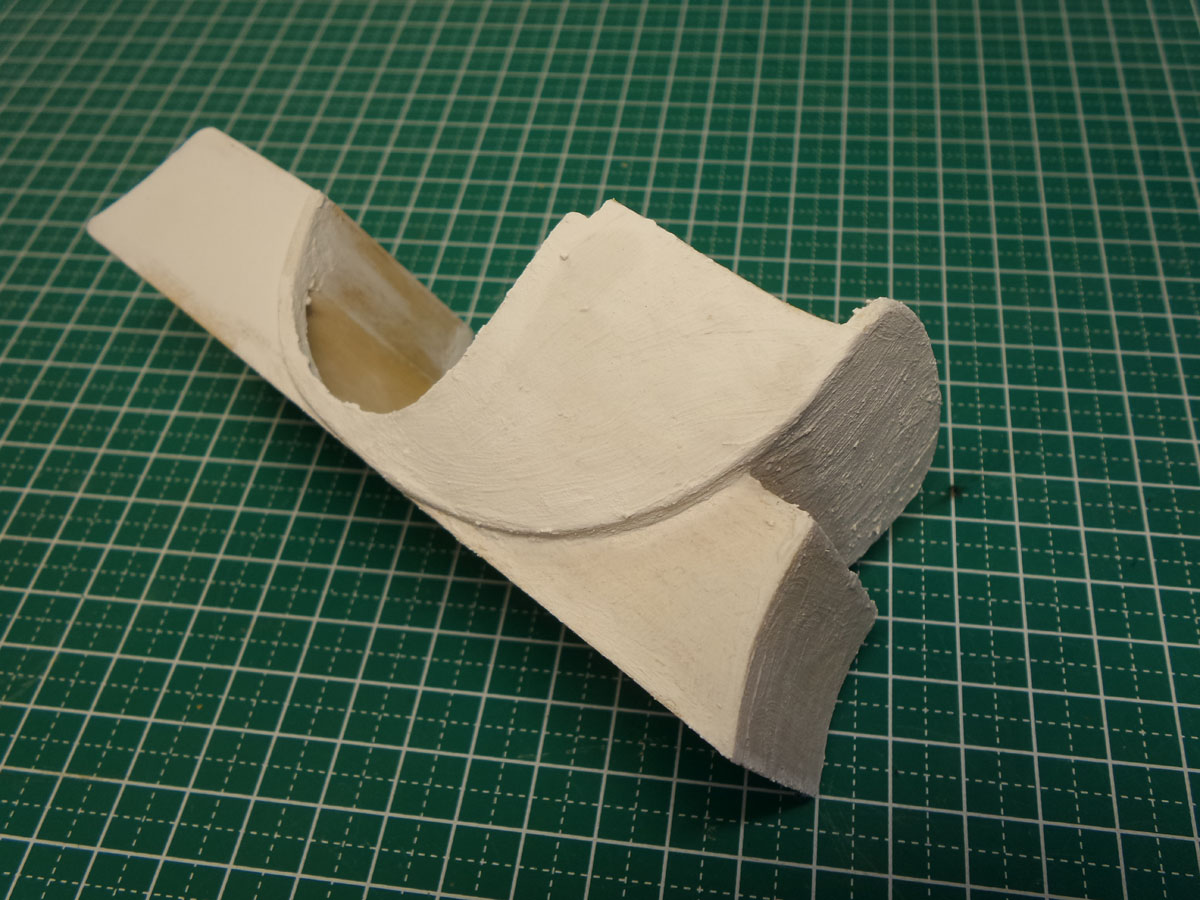

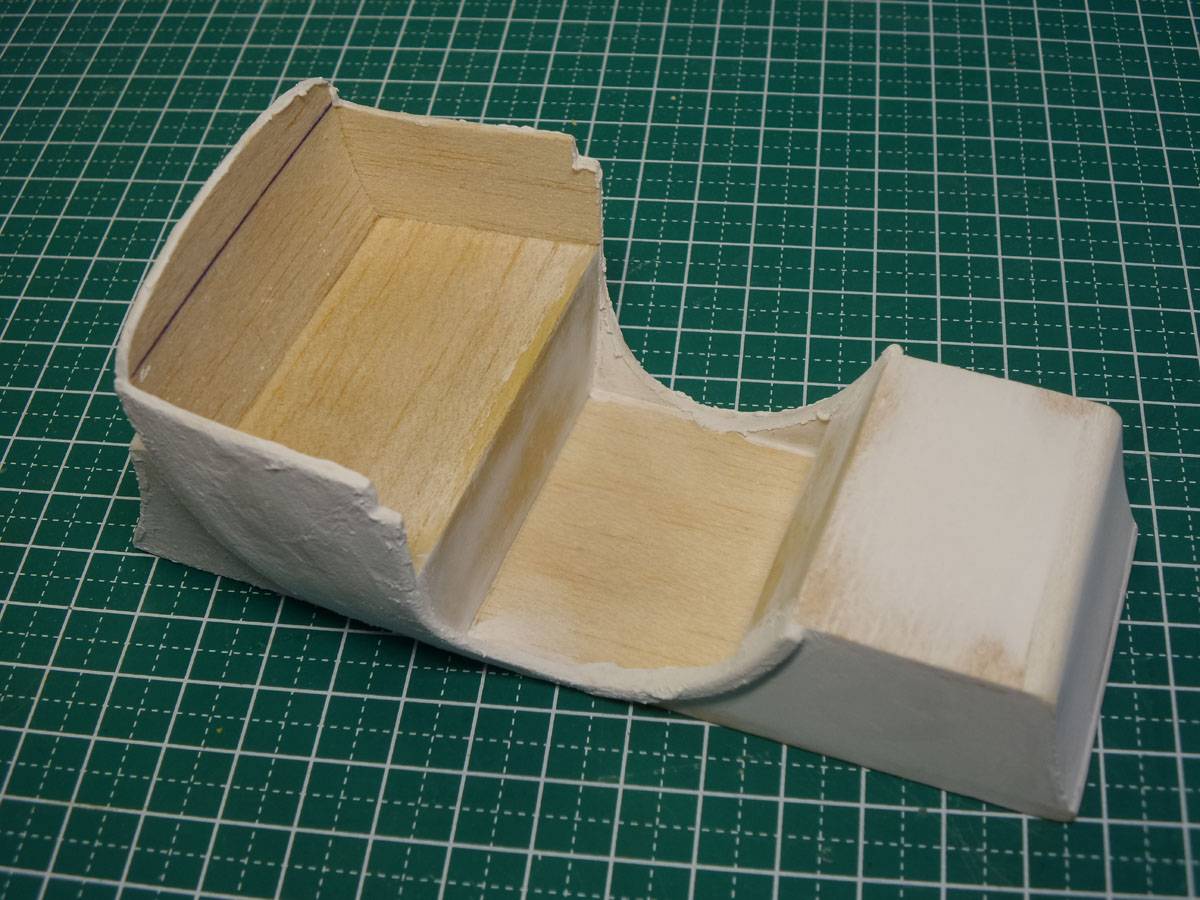

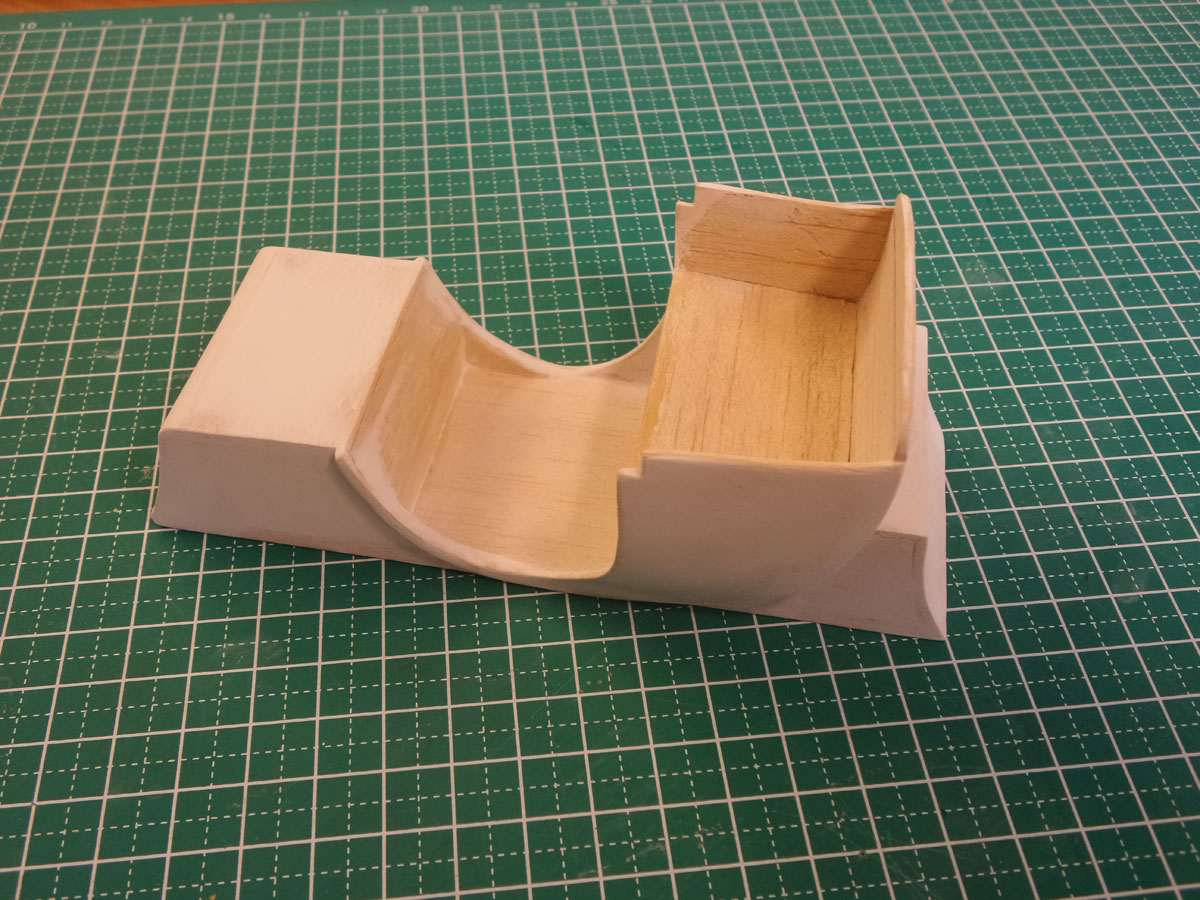

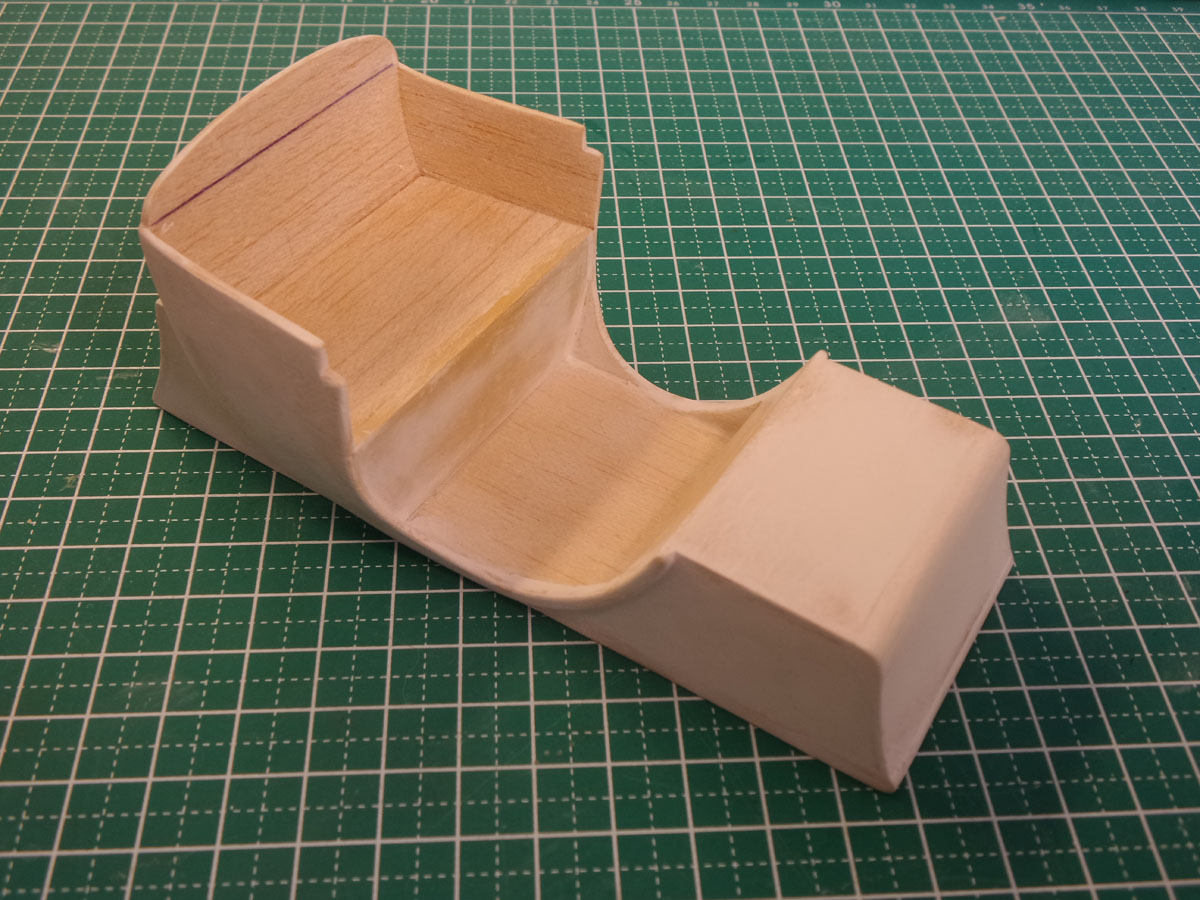

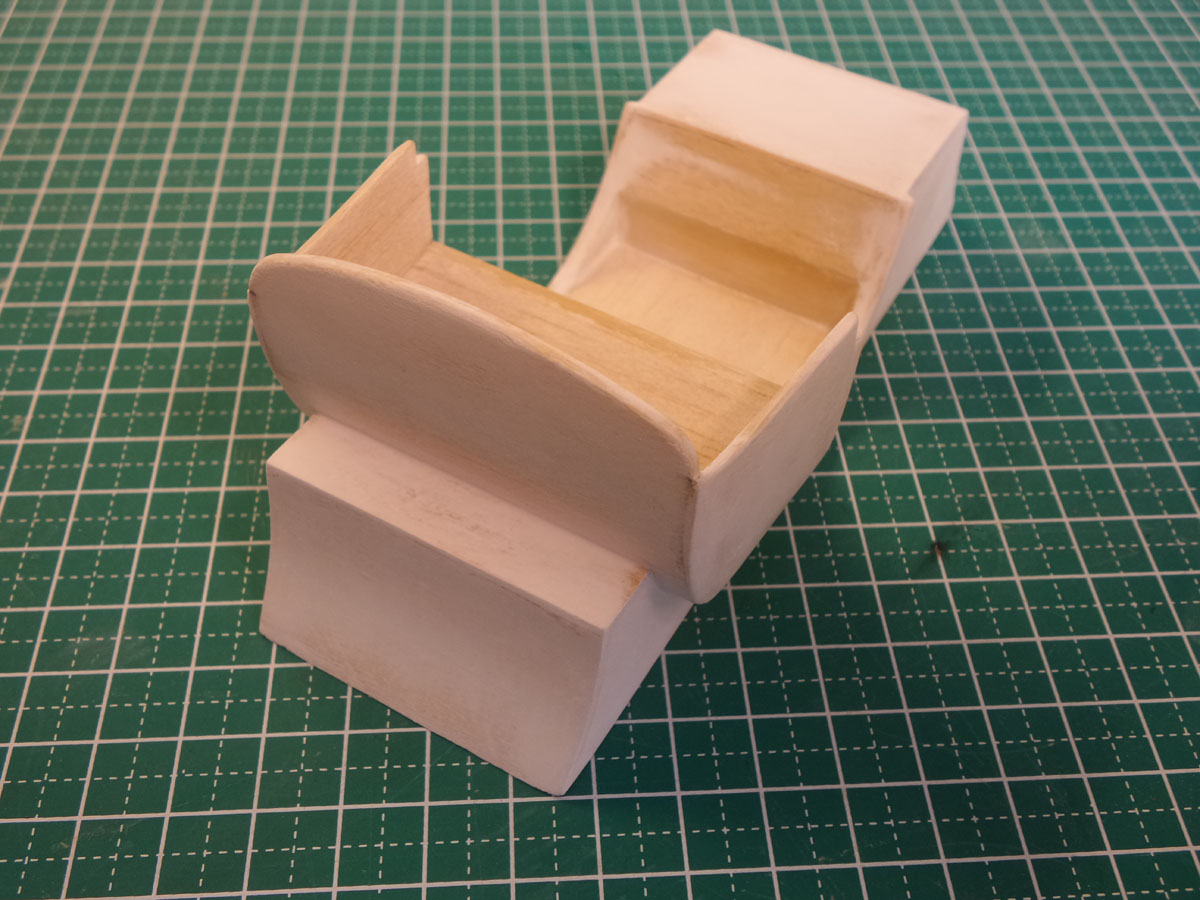

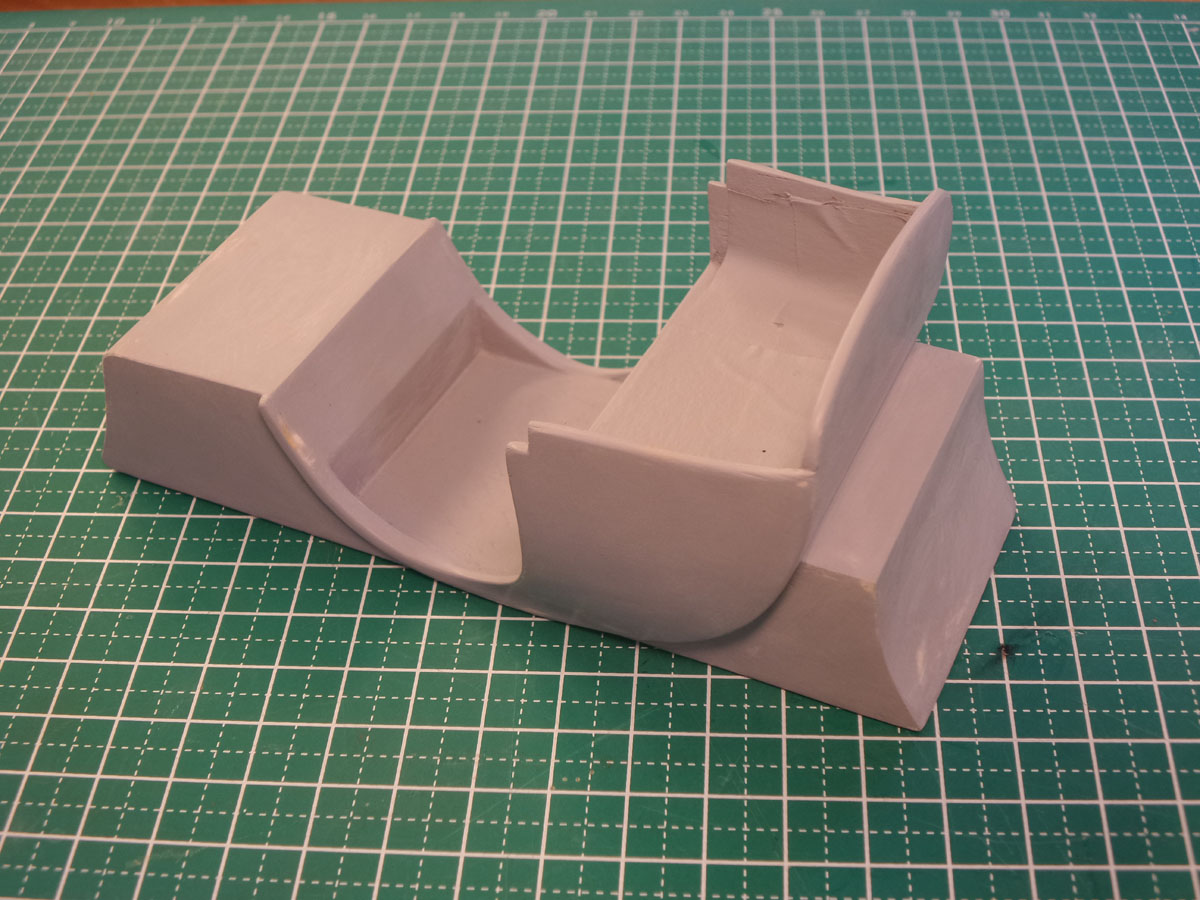

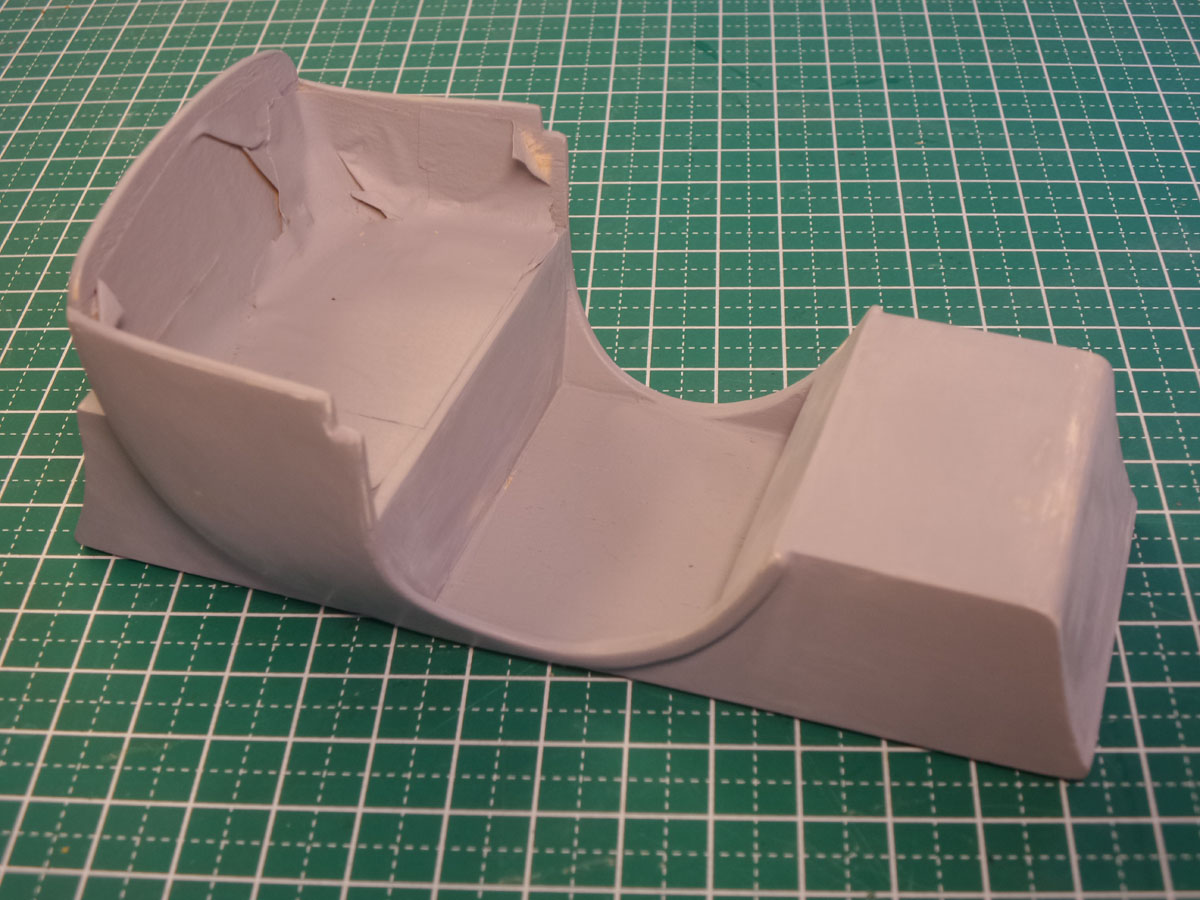

Brush, having diluted construction hard putty of Handycoat with water, I have covered a model body surface. I covered with a thin layer twice.

After that I have smoothed out everything an emery paper 600 and 800. Where there were hollows has puttied once again and too a brush.

Behind that I used spray of an automobile primer, previously having stuck the bottom and a seat with a painting adhesive tape. It is better to leave these places not painted over. After that I have processed all surface 1000 emery paper. Where it is necessary I puttied.

And the final – coloring. Paint in a barrel from the Korean producer. Generally somehow so